Enlistment warming is one of the novel techniques for straightforwardly warming an electrical metal part by circling electrical flows instead of a light or open fire. Acceptance warming machines depend on the qualities of radio recurrence energy moving intensity to the part through electromagnetic waves. There are a few advantages to induction heating equipment interaction.

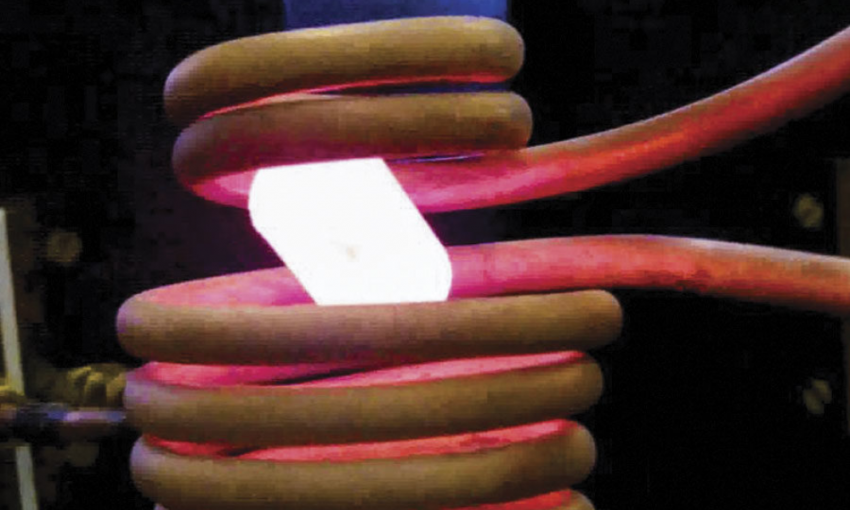

The part doesn’t come into contact with any fire while there is no gamble of pollution to the item. The inductor in the unit doesn’t get hot. These machines work on the rule of Faraday’s Law. A strong state radio recurrence power supply goes exchanging current through a copper curl inductor containing the warmed part.

The inductor fills in as the essential transformer while the warmed metal part is an optional short out. The metal part that enters the attractive field circles vortex flows inside the part.

The progression of whirlpool flows creates restricted heat with next to no contact made between the inductor and metal part and an induction melting furnace supplier can provide it bst.

Acceptance welding is utilized to mellow, solidify and bond metals and conductive materials. There is an assortment of drafting warming machines that offer a blend of consistency, speed and control for assembling processes.

Variables to Consider

The proficiency of acceptance warming machines relies upon a few elements. Hardly any elements incorporate the attributes of the part, inductor plan, limit of the power supply, and exact temperature expected for the application.

One can utilize an electrically leading item typically metals for enlistment welding. Plastics and other non-conductive materials require backhanded warming through a conductive metal subsector. Attractive materials are more straightforward to warm through this cycle since they have high porousness when contrasted with non-attractive materials.

Heat force, Power Supply and Inductor Design

Warming power is a significant variable to consider on the grounds that around 85% of the warming impact happens on the outer layer of conductive materials. Heat force diminishes with the increment of distance from the surface. Frequencies of 100 to 400 kHz are great for more modest parts, while longer warming cycles at lower frequencies are successful for profound, entering heat.

The size of the acceptance power supply is frequently determined by deciding how much energy move required for the work piece. This relies upon explicit intensity of the material, its mass, and the expected climb in temperature. The plan of the inductor is a significant perspective since the shifting attractive field expected for enlistment creates inside the inductor. The inductor gives the exact warming example and expands the effectiveness of the enlistment warming induction power supply.

Acceptance warming is speedy, clean and ecologically sounds, without fire, smoke, squandered intensity, clamor and poisonous emanations. You will find a scope of enlistment warming machines and dry ice impacting machines accessible for lease and rent.